Sheet Metal Bending Services

eMachineShop utilizes CNC bending equipment to complement our sheet metal cutting capabilities.

- 50+ Materials.

- FREE Shipping in the USA.

- 100% Quality Guaranteed.

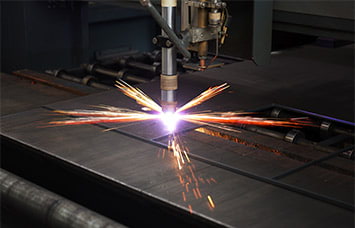

Sheet Metal Cutting Processes

Waterjet Cutting

Waterjets mainly cut sheet material into 2D parts using a high-pressure stream of water and abrasive. Waterjet cutting is suitable for most materials and yields clean edges.

Advanced Metal Cutting Services

Advanced metal cutting services are used to create custom metal parts with precise and accurate shapes and sizes. This process involves using advanced metal cutting technologies to create parts that meet the customer’s specifications. Advanced metal cutting services are often used to create complex shapes and sizes that are not possible with traditional sheet metal bending methods.

Importance of sheet metal bending

Sheet metal bending services are an important industrial process that is used to shape metal into various forms and shapes. The sheet metal services involve manipulating metal into various shapes, sizes, and angles with the use of specialized tools. We discussed the various aspects of sheet metal bending, including flat pattern, laser cutting services, custom sheet metal parts, and more. Sheet metal bending is used to create custom parts and components for a variety of industries and applications.

Sheet metal bending

Sheet metal bending is an important industrial process used to shape different types of metal material into various forms and configurations. Sheet metal bending is used to create custom parts and components for a variety of industries and applications. The process involves manipulating metal into different shapes, sizes, and angles with the use of specialized tools.

Below we review the various aspects of bending, including flat pattern, laser cutting and more. Our sheet metal folding service is an economical method of producing 3D parts from 2D sheet metal shapes. Forming custom metal products with precise and accurate shapes and sizes can be accomplished through the sheet metal bending process. Common applications include brackets, enclosures, cams and decorative items.

How sheet metal bending works

The bending process uses advanced tools and techniques to bend metal into complex shapes and sizes. Bent sheet metal parts are commonly made using a pneumatic or hydraulic press brake, where a metal sheet is pressed between a punch and die to bend it to the desired angle or shape. The press brake tool includes a wide variety of punches and dies which can form bends to a range of radii. After forming the bends, the products are sent to the quality control department to ensure accuracy.

eMachineShop Made Bent Parts

Materials for bending

eMachineShop regularly bends ductile metals such as aluminum 5052, stainless steel and brass. The thicknesses of metal sheet bending can be up to 0.25” or more. Inexpensive materials such as mild steel and aluminum can be used or more exotic metals such as titanium or silver. Before designing a model for a bending service, the material properties must be reviewed to see if it will form the desired bends at the needed thickness. Different metals, like magnesium, can be too brittle to properly bend; this material is prone to cracking in the press brake.

Compatible Materials

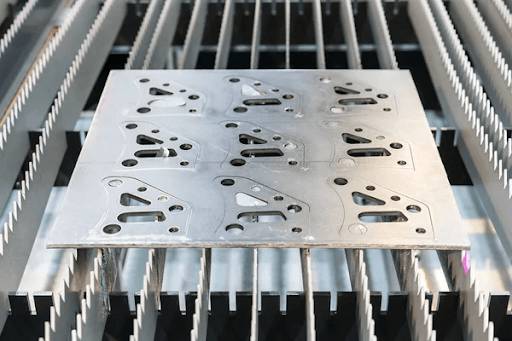

Flat Pattern

The free eMachineShop CAD software allows you to design parts for bending with a simple flat pattern method where the location and angle of bends is specified on the flat design. This process is used to form simple and complex shapes. After the flat pattern is specified, the process involves cutting and folding the metal in a specific sequence to create the desired shape. The flat pattern approach can be used for manufacturing simple sheet metal bending of a 2D sheet metal project or for more complex custom cut metal parts. Forming different metals in this way results in functional and attractive parts.

Preparation for bending

Prior to bending sheet metal, the sheet must be cut to the flat pattern. This can be accomplished by a variety of processes. Two of the most common CNC manufacturing processes used at eMachineShop are our laser cutting service and our waterjet cutting process. Laser cutting is a precise and accurate manufacturing process that is used to create custom metal parts. At eMachineShop, waterjet cutting offers quality custom metal cutting for thicker raw materials that can not be cut by traditional laser cutters. Waterjet is ideal for heavy sheet metal parts with thickness up to a few inches, however most jobs targeted for bending are below 0.25 inch.

Instant Quotes on Sheet Metal Bending

Instant quotes for our online metal cutting services provide an estimate of the cost of the project and the expected turnaround time. Instant quotes are useful for customers who need to get an estimate of the cost of their project quickly for both bending and competitive metal cutting. Quotes are also offered for complex metal bending services including assembly of PEM hardware and design services. At eMachineShop we have produced thousands of metal parts in both prototype and production quantities. Our pricing system can accurately quote prices based on the complexity of the design, material costs, and labor associated with secondary processes like bending or surface finishing.

Custom Sheet Metal Parts

Custom sheet metal parts are components that are designed and manufactured according to the customer’s specifications. These parts are typically produced using laser cutting services and 3D models. Custom metal parts can be used to create complex shapes and sizes that are not possible with traditional sheet metal bending methods. Custom metal bending can be applied to materials we supply or customer supplied materials.