Wire EDM Services

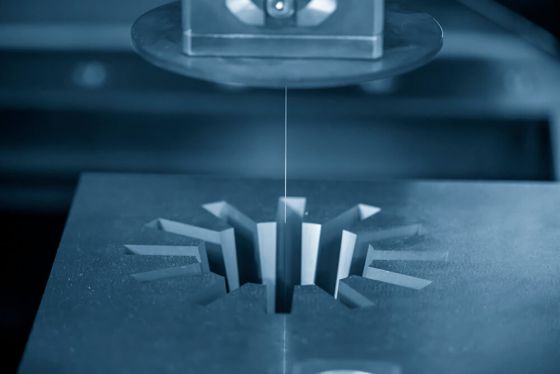

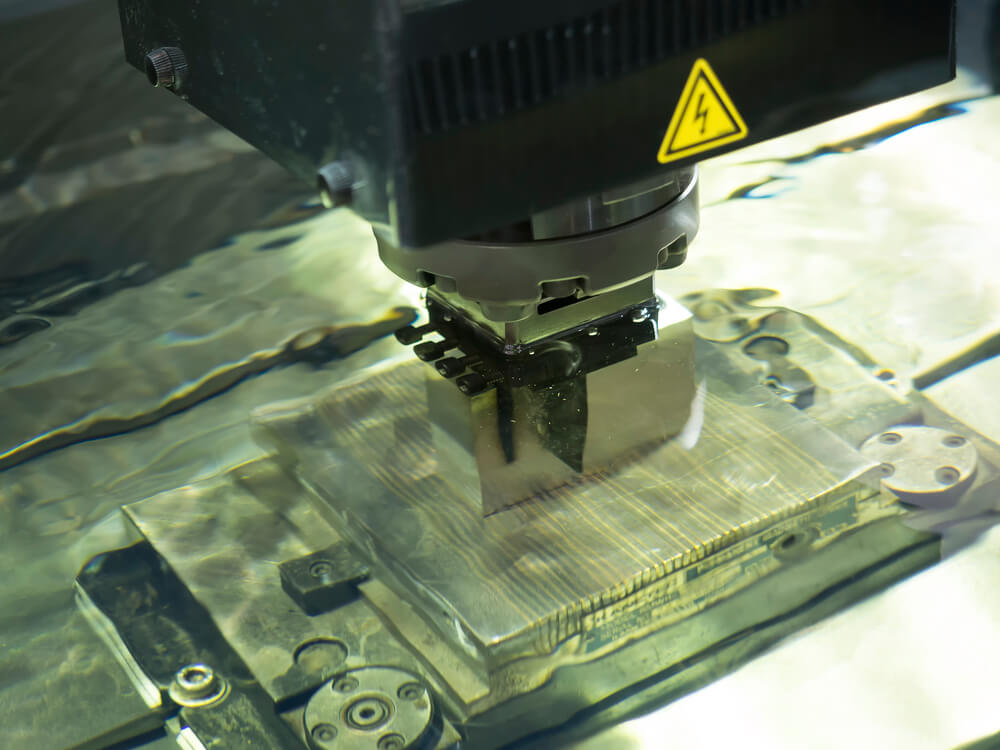

Electrical discharge machining, also known as EDM, is a process that uses sparks to cut shapes out of a workpiece.

eMachineShop offers sinker and wire EDM machining services whether you need a single part, batch of prototypes, or a production order.

- 50+ Materials.

- FREE Shipping in the USA.

- 100% Quality Guaranteed.

Advantages of Wire EDM

- Can produce sharp inside corners

- Ideal for parts with thin walls

- Ideal for metals with low machinability

- No burring

Wire EDM Design Considerations

- Material must be electrically conductive

- Typical surface finish will be between 16 and 64 microinches

- Kerf width typically ranges from 0.001″ to 0.012″

- Edges will be smooth but matte

Custom Wire EDM parts delivered to your door in days

eMachineShop offers wire EDM service and instant quotes for your wire EDM parts. Our customer service team will work with you to ensure your design specs are met. Order your part easily by following these steps:

-

Create or Upload your CAD file – Design your parts using our free CAD or upload your CAD files, PDF drawings, or images.

-

Configure your part – Select from over 50+ materials and surface finishes. Enter quantity, address and any special comments to the machinist.

-

Receive a quote – Get a quote for your design (instantly via our CAD).

-

Order your parts – Place your order and receive your quality CNC parts!

What does EDM stand for in machining?

EDM stands for Electrical Discharge Machining also known as Wire electrical discharge. It is a high precision metal fabrication process, which relies on a voltage of 50 to 300 volts and a thin wire to cut through metal to achieve a desired shape.

The origins of EDM machining can be traced back to 19th century scientists who began to use electrical sparks to erode metals. The process was further developed in the 20th century when engineers developed machines with high power functionality that could create enough spark for precision metal cutting. Modern CNC EDM machines are capable of producing high accuracy cuts of complex shapes that would otherwise be impractical through traditional machining methods.

What is Electric Discharge Machining?

Electric Discharge Machining (EDM) is a machining process that uses electrical sparks to cut through metal material by melting or vaporizing it. This cutting process is achieved by using electrical discharges between two electrodes which are separated by a dielectric liquid and subject to a varying amount of electrical voltage. Wire electrical discharge is a form of machining that is used for creating intricate and precise shapes and contours in parts that may have otherwise been unobtainable from more traditional CNC machining methods. One of the advantages is that EDM is used for machining parts made of materials that are usually difficult to machine with precision and quality control using standard methods, such as heat-treated steels, alloys, and special metals. The EDM process is capable of producing complex shapes with very tight tolerances. It can also machine narrow slots and small holes accurately, making it an invaluable tool for manufacturers and other engineering applications and industries.

Types of EDM

There are three types of EDM cutting processes. These include:

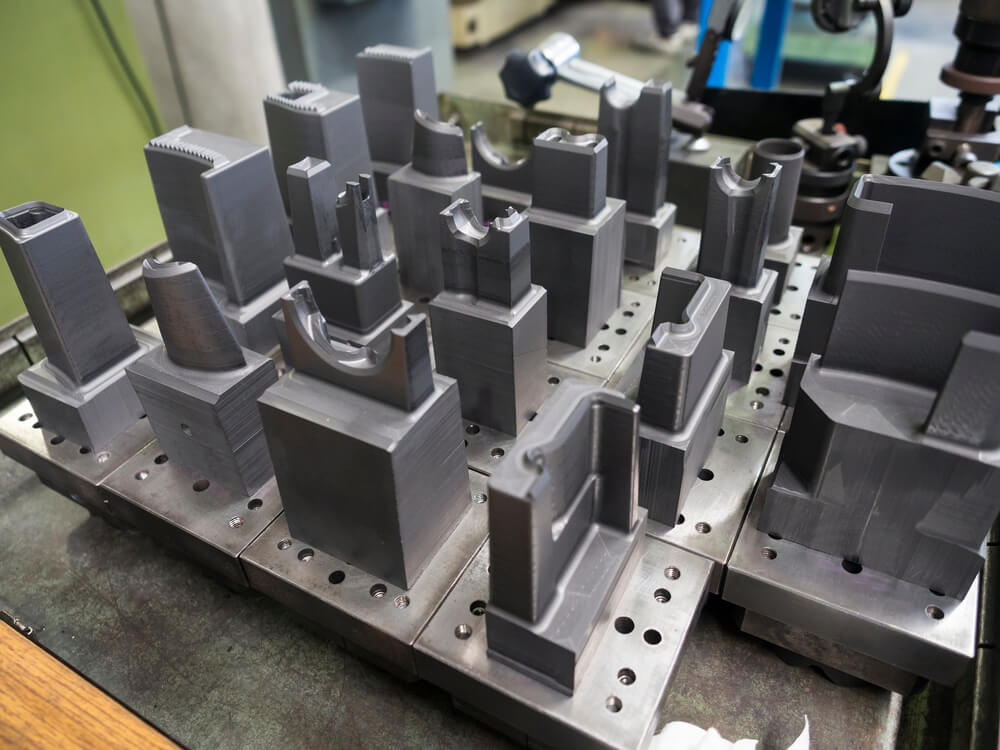

- Die sinking EDM – The die sinking EDM process is the conventional electric discharge machining process. Die sinking EDM uses a die to create complex features. Die sinking EDM involves the use of a die, which is an electrode made out of copper or graphite and is used to shape the metal. An electric current is passed through the die to erode the metal away in a controlled manner. The die is then gradually moved in order to create the desired shape while the material excess is flushed away in the dielectric fluid. This process is particularly useful for machining complex shapes that are difficult to create using conventional machining techniques and other EDM methods.

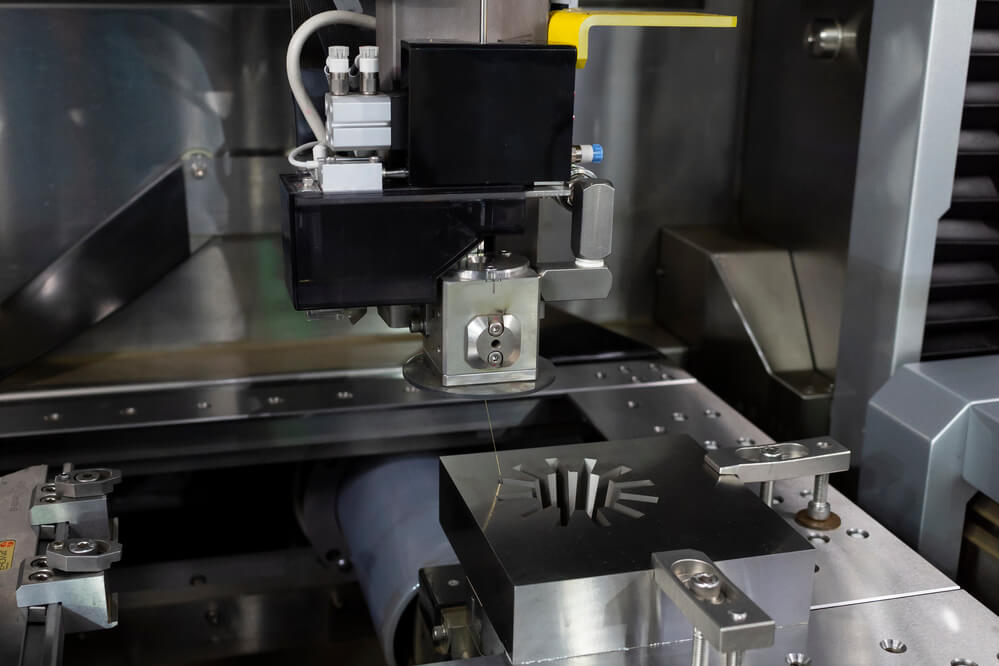

- Wire cut EDM – Something like a wire cutting through cheese, the wire EDM machining process relies on a thin wire that cuts through metal via spark erosion. Wire EDM works by using a thin wire to create sparks between the wire and the material being cut. The sparks erode the material and create a precise cut. This process can be used to cut complex shapes and intricate patterns. In many cases wire EDM is faster and more accurate than traditional machining methods, making it cost-effective for certain shapes. When two axis of motion are involved it results in parts with vertical edges and two-dimensional shapes. EDM wire cutting machines are capable of creating complex shapes with incredibly tight tolerances. Materials that can be cut by wire EDM include all conductive metals such as titanium, steel, aluminum, and brass.

- Hole drilling EDM – Hole drilling EDM is a machining process that uses electrical discharges to create holes in metals. The process is similar to conventional drilling, but instead of using a drill bit, an electrode is used to create sparks between the workpiece and electrode. The spark discharges melt or vaporize tiny amounts of the workpiece, which can then be further machined to the required size and shape. Hole drilling EDM is an extremely accurate and precise method of machining and can be used to create holes in very hard materials. Hole drilling EDM can create small and deep cavities in materials.

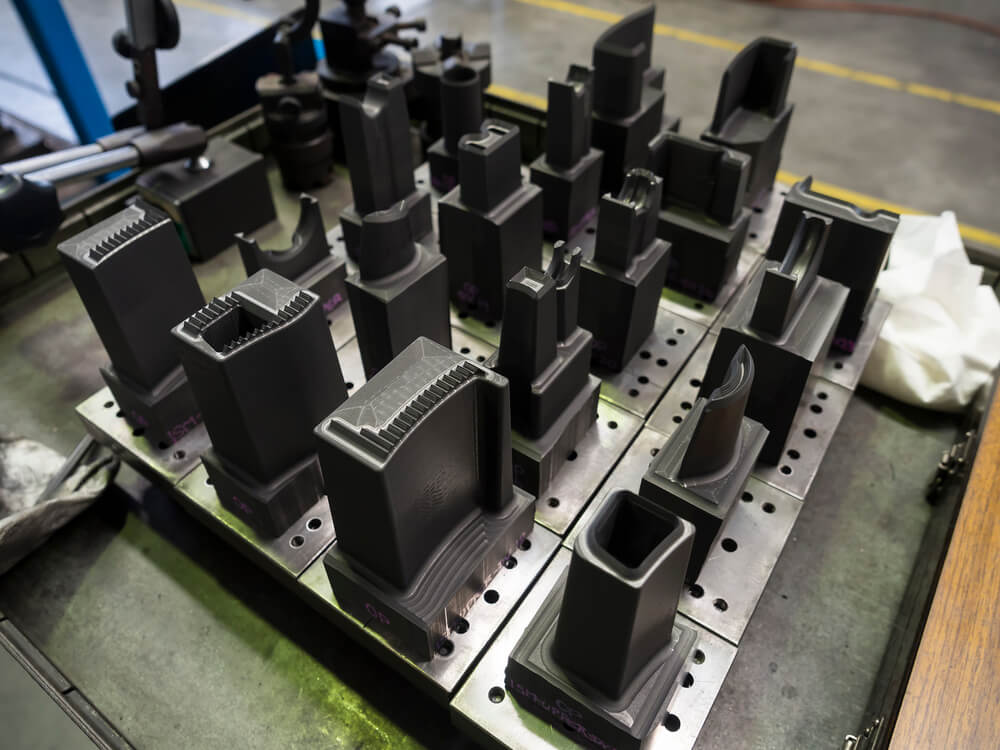

EDM Machining Service – Custom Parts

EDM machining equipment and cutting techniques can handle high volumes of steel, aluminum, and other metals with utmost accuracy. EDM machine shops provide EDM services including wire EDM, Die sinking EDM and hole drilling EDM.They make custom parts and metal components. Designing custom parts for EDM is a process that requires precision and accuracy. By utilizing EDM technology, engineers can create complex shapes and features that are not possible with traditional machining methods. EDM allows engineers to create parts that meet exact customer specifications and requirements, while also ensuring a high level of accuracy and quality, making the method an essential tool for engineers and manufacturers who are looking to create precision parts that meet their customer’s needs.

EDM Machining – Applications

Custom EDM parts and Wire EDM machining services are used in the production of aircraft, aerospace, watercraft, automotive equipment, electronics, medical devices, and circuit boards, to name a few industries. Wire EDM services are ideal for custom parts requiring complex cuts and shapes or incredibly tough material with tight tolerances for low and high volume runs. Custom parts with delicate sections can also be machined, achieving very fine holes without distortion since electrical discharge machining is non contact.

EDM machining precision cutting capabilities are used in:

- Transportation – The transportation industry relies on metals that cannot be easily machined through traditional manufacturing services. Wire EDM machines are reliable and efficient since they are capable of cutting ferrous and non ferrous metals and carbides and certain ceramics.

- Construction – Wire EDM services are suitable for heavy industrial applications and construction projects. Wire EDM machines are capable of cutting rigid materials and wire EDM parts are commonly used in manufacturing metal tools and components.

- Vehicles – Wire EDM machines are ideal for creating automotive mold parts for the vehicle industry since intricate holes and cavities can be customized including bumpers and plastic accessories.

- Air Travel – Wire EDM machines are ideal for producing parts that cannot withstand stress and high temperature, and that require tight tolerances. The air travel industry relies on wire EDM machines for the production of precise and accurate parts for engines, turbine blades, and many more components.

- Manufacturing – The tight tolerances achievable from EDM make it useful for tool and die making. Many tool and die fixtures require the use of hardened materials which are difficult to machine and work well with EDM.

- Aerospace – EDM machining is a key tool for the aerospace industry, allowing for the production of complex parts and components such as engine components to airframes. Many aerospace CAD engineers utilize the capabilities of titanium alloys since the metal can sustain hostile temperature climates.

Advantages of Die Sinking EDM

Die sinker EDM is capable of maintaining tight tolerances and good surface finishes on blind features that are difficult to attain using conventional machining. There are many advantages to using die sinker EDM:

- Capable of creating cavities and blind features (features that do not go all the way through the part)

- No forces generated from machining allowing for delicate features and brittle materials to be machined

- Can be easily automated and run without an operator

- Can produce good surface finishes without additional processing

- Precise parts with complex geometries are possible

- Can machine any conductive material as well as carbides and certain ceramics

Limitations of Die Sinking EDM

Die sinker EDM has many benefits and a wide range of capabilities. It also has several limitations that should be taken into consideration when deciding on a method of manufacturing parts.

- Material selection is limited to conductive materials

- Slow material removal rate when compared to other machining processes

- Electrodes can be expensive and they wear

- High cost associated with complex machines

- Due to the high heat generated by the sparks, there can be a small heat affected zone and recast layer left on the machined surface

- Secondary processing may be required to remove the recast layer

Advantages of Wire EDM

Wire EDM offers some distinct advantages to other processes such as CNC milling. Some of those advantages include:

- It is possible to machine sharp inside corners and other features that are difficult to machine on a CNC mill

- Extremely high tolerances can be achieved

- Tolerances are achievable down to a ten thousandth and surface finishes of 4 Ra(μin)

- Wire EDM can use up to five axes, allowing for complex shapes and tapered parts

- There are virtually no machining forces making it effective for thin featured parts

- Narrow features can be cut in thick material

- Precise cuts are very repeatable

- Cuts can be made that are just micrometers thick

- Can machine materials that are very hard such as carbides and graphite

- Can create holes as small as .015” in diameter

- Can cut multiple 2D parts at once if they are able to be stacked during machining

- Some machines allow for feed speeds up to 7 inches per minute depending on wire and workpiece material and thickness

- Does not leave tool marks or burrs

- Can cut materials up to 12 inches thick

Limitations of Wire EDM

Wire EDM is a very versatile process that has some traits that make it able to create parts with complex geometries with ease that are difficult to impossible by other machining operations. It also has some limitations that must be taken into consideration when determining if it is the right process for your parts. Some of these limitations include:

- It has a much slower material removal rate than CNC milling

- Only conductive materials are eligible for machining with wire EDM

- Slow machining and expensive consumables can make for high machining costs

- Tight tolerances and fine surface finishes require slow repeat passes increasing machining time

- The wire is no longer usable after one use so the wire needs constant replenishing

- Wire EDM cannot be used for blind features and cavities, the wire must pass all the way through the part to the bottom wire guide

- Deionized water is required for machining

- Deionized water needs to have a system that can filter and deionize the water as the machine is cutting

- Due to the high heat generated by the sparks, there can be a small heat affected zone and a recast layer left on the machined surface

- Secondary processing may be required to remove the recast layer

EDM Machining Services in Manufacturing

CNC EDM is a powerful tool used by engineers and manufacturers to create precision parts with accuracy, quality, and a superior finish. This process uses dielectric fluid to erode metal with electrical sparks, allowing for greater control and accuracy than traditional machining methods. CNC EDM works quickly and efficiently, and can be used to create complex shapes and features in parts for a variety of different industries. CNC EDM is available in a range of power and speed settings, allowing manufacturers to customize their design to suit their specific needs and requirements. By utilizing this technology as a tool, manufacturers can reduce the time and effort required to create high-quality parts, allowing them to focus on other areas of the engineering process.