3D Printing Service

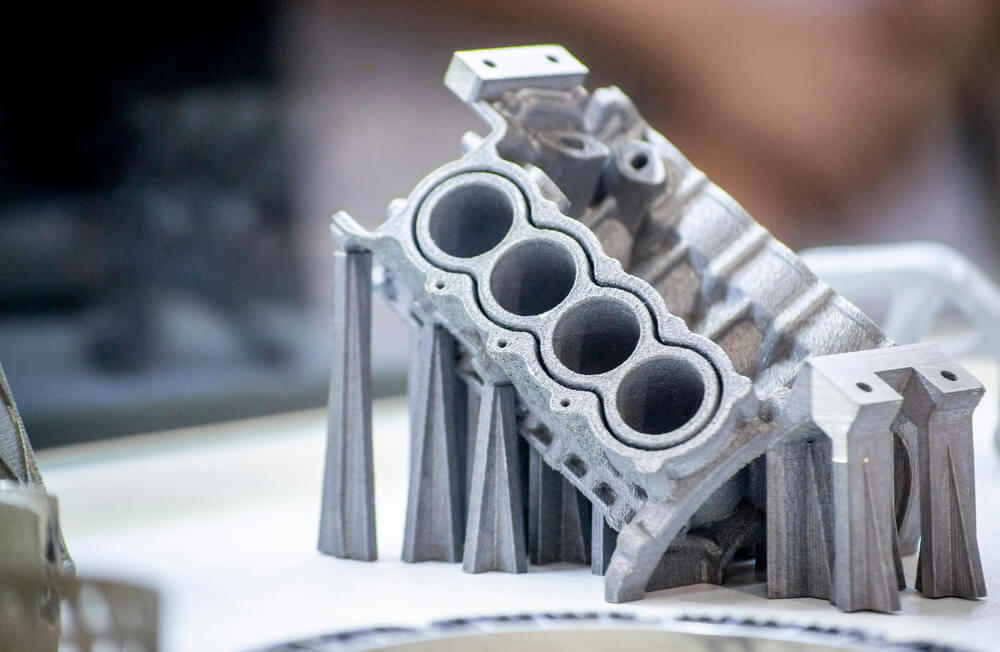

Also known as rapid prototyping, 3D printing is an additive manufacturing process that quickly produces complex parts of nearly any shape.

eMachineShop offers cost-effective SLS printing whether you need a single part or a run of prototypes.

- 50+ Materials.

- FREE Shipping in the USA.

- 100% Quality Guaranteed.

Advantages of 3D Printing

- Fast turns

- Can produce 2D and 3D parts of almost any shape

- Ideal for prototyping and short runs

- SLS printed parts don’t require support structures

3D Printing Design Tips

- Make all pins, protrusions, and similar features at least 0.8mm

- Make hole diameters larger than 1.5mm

- Make the part as hollow as possible to decrease costs

- Add ribs to flat surfaces to minimize warping

What is 3D printing?

3D printing is an innovative technology that is transforming the way parts can be designed and manufactured in both commercial and hobbyist settings. 3D printing services take three dimensional models and produce them by laying down successive layers of material until the models are completed. The 3D printing process is extremely cost-effective and has been implemented in a wide array of products and industries such as medical, automotive, aviation, and consumer goods.

While most CNC machining processes use subtractive machining, where a part is carved out of a larger stock material, 3D printing services are unique since they are a layer-by-layer additive process. This allows for CAD users to create and manufacture designs that were previously difficult or impossible to produce with traditional CNC machining.

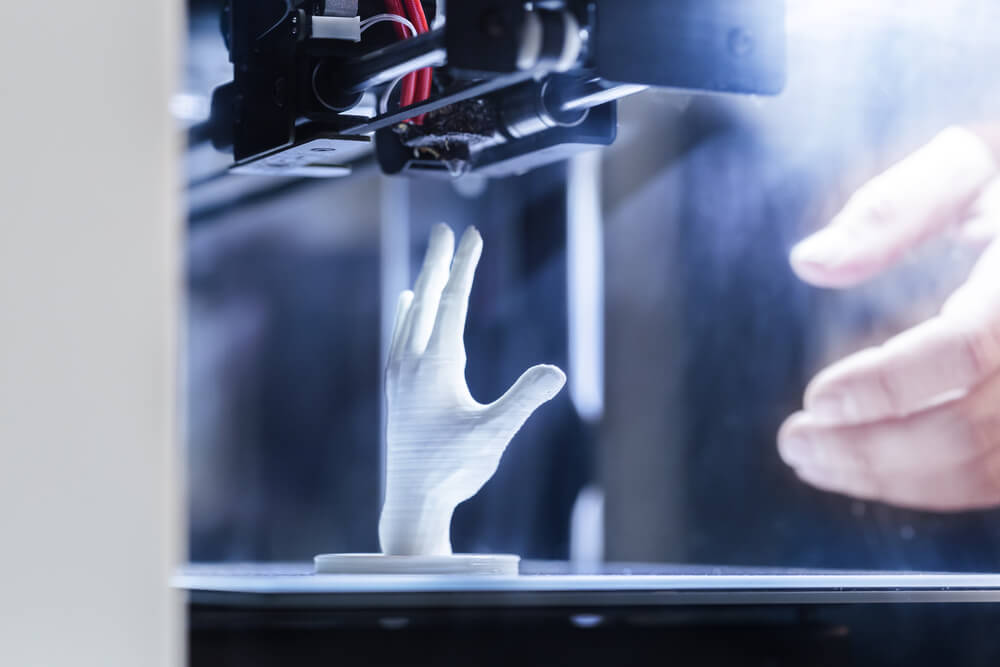

3D printing services are the ideal choice for businesses and hobbyists that need rapid prototyping or low volume production runs for their plastic products since models can be printed quickly and efficiently without compromising quality or long turn times. eMachineShop also offers metal 3D printing.

How does the 3D printing process work?

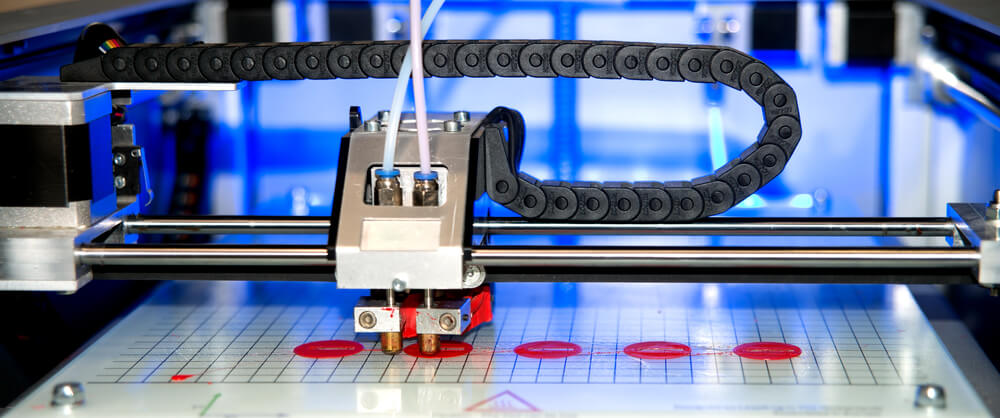

The 3D printing process all starts with the 3D CAD model. The 3D model is exported and converted into an STL file, this file format is specifically designed for 3D printing. Once properly converted, the STL file is then sliced into thin cross-sectional layers and instructions are sent to the 3D printer where it begins the production process. The printer then begins to create material deposits beginning at the base of the object and successively adds additional layers, until the 3D model is completed. Depending on the 3D printer being used, a wide array of materials can be used such as plastic, metal, or ceramic. Once the model is completed, it is removed from the printer and sent to any needed secondary processes, like sanding, painting, or coating.

Since 3D printing technology is able to print models quickly and efficiently, it makes it the ideal manufacturing process for low production runs and rapid prototyping compared to other CNC operations. The process is more cost-effective and less time consuming than machining.

Origins of 3D printing

The origins of 3D printing go back to the 1980’s when the first 3D printer was developed by an engineer named Chuck Hull. Hull’s printer used a process called photopolymerization to create a 3D model based on an existing design file. The photopolymerization process involved projecting UV lights on a vat of liquid photopolymer which would later solidify as a single layer. The layer created would match the base of the 3D model and would repeatedly add additional layers, which coincided with the model’s dimensions, until the 3D object was completed.

The power, capacity, and availability of 3D printing has vastly expanded since the fledgling days of its early development. 3D printers have evolved over the past few decades into a technology that is continually progressing and becoming more accessible for both large volume manufacturers and at home hobbyists. 3D printers have also progressed to use a multitude of materials, from plastic to metals, which has allowed the manufacturing process to be applicable in numerous industries such as aerospace, aviation, medical prosthetics and more.

Benefits of 3D Printing

3D printing is a state of the art technology that offers a range of benefits for prototyping and low volume production runs. It is a rapid process which produces high quality prototypes in a fraction of the time that traditional manufacturing processes require. It is also possible to print with a variety of metals and plastics, such as nylon, polyethylene, and aluminum. Since 3D printing services can print prototypes from a large array of compatible materials it also allows the end user to add color and other cosmetic features without needing secondary processes, such as painting or polishing. The process of 3D printing is not only rapid but also cost effective, allowing businesses to produce products with a high level of quality in a short amount of time. 3D printing also offers the flexibility to make changes to a design or prototype model quickly and cost-effectively, allowing businesses to respond quickly to changing customer needs. Furthermore, those interested in 3D printing can learn the process relatively quickly, making it a great technology for entrepreneurs and hobbyists to take advantage of.

Terminology

Some common terminology words used in 3d printing include:

- 3D Printer: A machine that creates three-dimensional objects by layering materials such as plastics, metals, or ceramics.

- Extrusion: A 3D printing process where melted plastic is forced through a nozzle and laid down in layers to create an object.

- Extruder: The part of the 3D printer that deposits the material.

- STL file: A type of file specifically designed for 3D printing (Stereolithography file).

- 3D model: A digital representation of a 3D object created in a CAD program.

- G-Code: A set of commands that instructs a 3D printer what to do when creating an object.

- Layer: The individual slices of material that are deposited one-by-one to create a 3D object.

- Resolution: The smallest size of feature that a 3D printer can accurately produce.

- Layer Height: The thickness of each layer of material that is laid down by a 3D printer.

- Infill: The internal structure of a 3D printed object, which can be varied to adjust the strength or weight of the object.

- Support Material: A material used to provide support during 3D printing, which is usually removed after printing is complete.

- Build Plate: The surface on which a 3D printed object is created.

- Post-processing: Any additional steps taken to give the 3D object its final look, such as sanding, painting, or coating.

- FDM/FFF: Fused Deposition Modeling/ Fused Filament Fabrication, a type of 3D printing that uses a filament of molten material which is then deposited layer-by-layer.

- Fused Filament Fabrication (FFF): A 3D printing process where a filament of thermoplastic like nylon,is heated and then extruded through a nozzle in layers to form an object.

- Stereolithography (SLA): A 3D printing process where a laser is used to cure and solidify a liquid resin.

- Selective Laser Sintering (SLS): A 3D printing process where a laser is used to bind together small particles of powder.

- Direct Metal Laser Sintering (DMLS): A 3D printing process where a laser is used to fuse and bind metal particles.

Design Tips and Tricks

Although the 3D printing process approach to manufacturing is fairly straightforward, there are still some nuances to learn in designing 3D models that can help ensure the final product or prototype has the needed quality and integrity the design requires for real world applications.

When designing models for a 3D printing service, taking these factors into consideration will help reduce the time needed for prototyping and testing the printed product.

Some easy to execute design tips for 3D manufacturing include:

3D Printing Materials and Specifications

|

Material Name

|

Process

|

Specifications

|

Min Size (mm)

|

Max Size (mm)

|

Tolerance (mm)

|

Clearance (mm)

|

Min Supported Walls (mm)

|

Min Unsupported Walls (mm)

|

Min Supported Wires (mm)

|

Min Unsupported Wires (mm)

|

Min Emboss Details (High and Wide) (mm)

|

Min Emboss Text (High and Wide) (mm)

|

Min Engrave Details (Deep and Wide) (mm)

|

Min Engrave Text (Deep and Wide) (mm)

|

Single Escape Hole Diameter (mm)

|

Multiple Escape Hole Diameter (mm)

|

Multiple Parts per File

|

Interlocking OK

|

Enclosed OK

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum AlSi10Mg – Matte | Selective Laser Melting (SLM) | ≈ 88.4% Al, 10% Si, 0.35% Mg, <1.25% Other | X + Y + Z > 30 | 250 x 250 x 200 | +/- (0.2mm + 1.5%) | 0.6 | 1 | 1 | 1.5 | 1.5 | 0.4 | 0.8 | 0.4 | 1 | 4 | 2 | No | Yes | No |

| Stainless Steel 420, Bronze Infused – Matte Black | Binder Jetting | 60% Stainless Steel, 40% Bronze Matrix | 2.5 × 2.5 × 3 | 762 × 393 × 393 | +/- (0.1 mm + 5.0%) | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 2 | No | No | No |

| Stainless Steel 420, Bronze Infused – Polished Bronzed Black | Binder Jetting | 60% Stainless Steel, 40% Bronze Matrix | 2.5 × 2.5 × 3 | 762 × 393 × 393 | +/- (0.1 mm + 5.0%) | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 2 | No | No | No |

| Stainless Steel 420, Bronze Infused – Matte Bronzed Silver | Binder Jetting | 60% Stainless Steel, 40% Bronze Matrix | 2.5 × 2.5 × 3 | 762 × 393 × 393 | +/- (0.1 mm + 5.0%) | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 2 | No | No | No |

| Stainless Steel 420, Bronze Infused – Polished Bronzed Silver | Binder Jetting | 60% Stainless Steel, 40% Bronze Matrix | 2.5 × 2.5 × 3 | 762 × 393 × 393 | +/- (0.1 mm + 5.0%) | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 2 | No | No | No |

| Stainless Steel 420, Bronze Infused – Polished Bronze | Binder Jetting | 60% Stainless Steel, 40% Bronze Matrix | 2.5 × 2.5 × 3 | 762 × 393 × 393 | +/- (0.1 mm + 5.0%) | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 2 | No | No | No |

| Stainless Steel 420, Bronze Infused – Polished Gold | Binder Jetting | 60% Stainless Steel, 40% Bronze Matrix | 2.5 × 2.5 × 3 | 178 × 178 × 178 | +/- (0.1 mm + 5.0%) | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 2 | No | No | No |

| Stainless Steel 420, Bronze Infused – Polished Nickel | Binder Jetting | 60% Stainless Steel, 40% Bronze Matrix | 2.5 × 2.5 × 3 | 178 × 178 × 178 | +/- (0.1 mm + 5.0%) | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 4 | 2 | No | No | No |

| Silver – Lightly Polished | Lost Wax Casting | 92.5% Ag | 2.4 × 2.4 × 0.6 | 89 × 89 × 100 | +/- (0.15 mm + 1.5%) | 0.3 | 0.6 | 0.6 | 0.8 | 1 | 0.4 | 0.4 | 0.35 | 0.35 | 4 | 2 | No | No | No |

| Silver – Lightly Polished (Interlocking) | Lost Wax Casting | 92.5% Ag | 2.4 × 2.4 × 0.6 | 75 × 75 × 40 | +/- (0.15 mm + 1.5%) | 1 | 0.8 | 0.8 | 1.5 | 1.5 | 0.4 | 0.4 | 0.35 | 0.35 | 4 | 2 | No | ≤6 | ≤6 |

| Silver – Polished | Lost Wax Casting | 92.5% Ag | 2.4 × 2.4 × 0.6 | 89 × 89 × 100 | +/- (0.25 mm + 2.5%) | 0.3 | 0.8 | 0.8 | 0.8 | 1 | 0.4 | 0.4 | 0.35 | 0.35 | 4 | 2 | No | No | No |

| Silver – Polished (Interlocking) | Lost Wax Casting | 92.5% Ag | 2.4 × 2.4 × 0.6 | 75 × 75 × 40 | +/- (0.25 mm + 2.5%) | 1 | 0.8 | 0.8 | 1.5 | 1.5 | 0.4 | 0.4 | 0.35 | 0.35 | 4 | 2 | No | ≤6 | ≤6 |

| Silver – Extensively Polished | Lost Wax Casting | 92.5% Ag | 2.4 × 2.4 × 0.6 | 89 × 89 × 100 | +/- (0.25 mm + 2.5%) | 0.3 | 0.8 | 0.8 | 0.8 | 1 | 0.4 | 0.4 | 0.35 | 0.35 | 4 | 2 | No | No | No |

| Silver – Aged | Lost Wax Casting | 92.5% Ag, Recesses Darkened | 2.4 × 2.4 × 0.6 | 89 × 89 × 100 | +/- (0.25 mm + 2.5%) | 0.3 | 0.8 | 0.8 | 0.8 | 1 | 0.4 | 0.4 | 0.35 | 0.35 | 4 | 2 | No | No | No |

| Nylon PA 2200 – Matte White | Selective Laser Sintering (SLS) | X + Y + Z ≥ 7.5 | 650 × 350 × 550 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.8 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes | |

| Nylon PA 2200 – Matte Black | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 7.5 | 180 × 230 × 320 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.8 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Nylon PA 2200 – Smooth White | Selective Laser Sintering (SLS) | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes | |

| Nylon PA 2200 – Smoothest White | Selective Laser Sintering (SLS) | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes | |

| Nylon PA 2200 – Smoothest Black | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Nylon PA 2200 – Smooth Blue | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Nylon PA 2200 – Smooth Green | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Nylon PA 2200 – Smooth Red | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Nylon PA 2200 – Smooth Orange | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Nylon PA 2200 – Smooth Yellow | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Nylon PA 2200 – Smooth Purple | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Nylon PA 2200 – Smooth Pink | Selective Laser Sintering (SLS) | Dyed | X + Y + Z ≥ 25 and axes must be ≥ 2.5 | 200 × 150 × 150 | +/- (0.01″ + 0.15%) | 0.5 | 0.7 | 0.7 | 0.9 | 1 | 0.2 | 0.5 | 0.2 | 0.5 | 4 | 2 | No | Yes | Yes |

| Acrylic Photopolymer – Smooth Frosted Clear | Material Jetting | Fine Detail | X + Y + Z > 12 | 282 × 181 × 150 | +/- (0.3 mm + 0.7%) | 0.05 | 0.3 | 0.6 | 0.6 | 0.8 | 0.1 | 0.1 | 0.1 | 0.1 | N/A | 4 | No | Yes | No |

| Acrylic Photopolymer – Smoothest Frosted Clear | Material Jetting | Fine Detail | X + Y + Z > 12 | 282 × 181 × 100 | +/- (0.3 mm + 0.7%) | 0.05 | 0.3 | 0.6 | 0.6 | 0.8 | 0.1 | 0.1 | 0.1 | 0.1 | N/A | 4 | No | Yes | No |

| TPU Thermoplastic Polyurethane – Matte Off-White | Selective Laser Sintering (SLS) | Rubber-Like | 15 x 15 x 0.7 , X + Y + Z ≥ 15 | 200 x 200 x 200 | +/- (0.3 mm + 0.7%) | 1 | 0.7 | 0.7 | 1 | 2 | 1 | 1 | 1.5 | 1.5 | 4 | 3 | No | Yes | Yes |

Popular 3D Printing Materials

Plastics

- ABS (Acrylonitrile Butadiene Styrene) is a durable, heat-resistant plastic that is commonly used for prototyping and functional parts. It is easy to sand and paint, and can be used with a variety of 3D printing technologies. ABS plastic also allows for the color of the material to be accurately dyed.

- PLA (Polylactic Acid) is a biodegradable plastic that is often used for low-stress applications. It is easy to use, and is often the material of choice for hobbyists and beginners due to its low cost and ease of use.

- Nylon is a strong, lightweight material that is often used for functional parts. It is highly durable and has a low coefficient of friction, making nylon the ideal material for parts that require wear resistance. Although nylon is typically seen in an off-white color, it’s ability to accept dyes allows a 3D printing service to make nylon in numerous colors.

- PETG (Polyethylene terephthalate glycol-modified) is a strong and flexible plastic that is often used for parts that require impact resistance. It is also easy to print, and is often the material of choice for hobbyists and beginners.

- TPU (Thermoplastic polyurethane) is a flexible and elastic material that is often used for parts that require flexibility or elasticity. It is a durable material and has good chemical resistance, making it a good choice for parts that require flexibility and durability. TPU can not easily take color from dye but it works well with numerous types of paint.

Metals

- Aluminum is a lightweight metal that is often used for parts that require low density and high strength. It is easy to machine and can be used in a variety of 3D printing technologies.

- Stainless steel is a strong and corrosion-resistant metal that is often used for functional parts. It is easy to machine and has a low coefficient of friction, making steel an ideal material for parts that require wear resistance.

- Titanium is a lightweight metal that is often used for parts that require high strength and stiffness. It is highly durable and has a low coefficient of friction, making it an ideal material for parts that require wear resistance.

- Bronze is a strong and corrosion-resistant metal that is often used for functional parts. It is easy to machine and is often the material of choice for hobbyists and beginners due to its low cost and ease of use.

- Silver is malleable, durable, and cost-effective. It is also highly conductive metal, making it ideal for electrical components. This metal material is also aesthetically pleasing making it an ideal choice for consumer grade products. Silver is also typically more environmentally friendly compared to its metal counterparts.

Compatible Materials

When to choose 3D printing?

3D printing is an ideal choice for prototyping, small-scale production, and highly complex geometries. It allows for quick turnaround and minimal material waste, making it an excellent choice for custom parts. 3D printing is also well-suited for creating complex shapes, such as those with overhangs, that would be difficult or impossible to create using traditional manufacturing methods.

On the other hand, milling machines, lathes and other traditional manufacturing processes are better suited for large-scale production runs and parts with standard geometries, such as cylinders and cubes, because they are more cost-effective and are capable of producing parts quickly and efficiently at that production volume.

The different types of 3D printing

There are several different types of 3D printing

- Fused Filament Fabrication (FFF), is the most common type of 3D printing. It uses a continuous filament of plastic material, which is fed into an extrusion nozzle heated to its melting point. The nozzle then deposits the plastic in thin layers on the build plate, creating the desired 3D object. The process is relatively simple and cost-effective compared to other 3D printing processes, and it can produce high-resolution objects with a good surface finish. FFF 3D printing is ideal for prototyping, custom parts, and small-batch production.

- Stereolithography (SLA), is a 3D printing process that uses photosensitive liquid resin to create 3D objects. The part is built layer by layer, using an ultraviolet laser to cure the resin and shape the part. This process allows for the production of highly detailed and accurate parts with excellent surface finish. SLA is also known for its high resolution and speed, making it a great choice for prototyping and small-batch production. The relatively low cost of materials and equipment make it an attractive option for businesses.

- Selective Laser Sintering (SLS), is a 3D printing process that uses lasers to fuse particles of various materials, such as nylon, metal, ceramic, and plastic. The laser is used to selectively fuse the particles layer by layer, creating a 3D object. This process is great for producing durable complex parts with excellent surface finish.

- Direct Metal Laser Sintering (DMLS), is a 3D printing process that uses lasers to fuse particles of metal, such as stainless steel, titanium, and aluminum. The laser is used to selectively fuse the particles layer by layer, creating a 3D metal object.

Each type of 3D printing service has its own unique advantages and disadvantages which makes it important to select the right type for the desired application.

Economical 3D Printing

Since its conception in the 1980s, 3D printing has revolutionized the manufacturing industry, offering a fast, cost-effective, and precise way to create complex objects. Over the decades, a variety of 3D printing techniques have been developed, such as Fused Filament Fabrication (FFF), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS). These techniques can be used to create objects from a wide variety of materials, including plastic, metal, and ceramic. 3D printing allows for intricate and complex designs, making it ideal for prototyping and custom parts. When designing for 3D printing, it is important to consider factors such as wall thickness, overhangs, and orientation. With these considerations in mind, 3D printing is an invaluable tool for today’s manufacturing industry, allowing for quick turnaround and minimal material waste.