Custom Manufacturing Made Easy

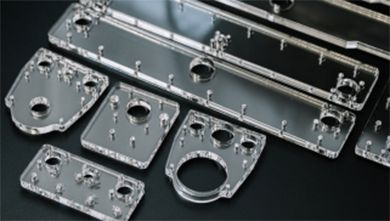

eMachineShop offers CNC machining, sheet metal fabrication, 3D printing, injection molding and various finishing options. Simply upload your design, enter your specifications and get a reliable manufacturing quote.

- Over 50+ Metal and Plastic Materials Available

- Rapid Prototyping and Full Production Runs

- Quick Turn Times and Quality Assured Manufacturing

As Seen In:

Manufacturing Services

Simplified Custom CNC Manufacturing

Upload your CAD files with any supplemental files for tolerances, threading, etc.

Select your material from over 50 metals and plastics, quantity, finishing option, and any special comments.

Get a fast quote using your own CAD files or an instant quote using eMachineShop free CAD software.

Easily place your order using our free CAD software or following a payment link included within your quote.

Why choose eMachineShop?

Prototype to Production – Order any quantity. No minimum or maximum limits.

Novices and Engineers – If you are new to custom manufacturing, try our easy free CAD software. If you’re a pro, just provide us with your CAD file.

Great customer service – We will be at your side from design to order tracking.

Free shipping – No charge for ground shipping in the continental USA.

Quality Ensured with Expertise

As a company committed to delivering high-quality products, we implement strict standards throughout our manufacturing processes to ensure accuracy, precision, and consistency. Our manufacturing facilities are equipped with top of the line equipment to accommodate rapid prototyping and production runs while maintaining tight tolerances and quick turn times. Our procedures ensure every manufactured part meets our high-quality standards and your specified requirements.

Experienced Technical Support

Technical Support Representatives are committed to providing quick and informative support

Dedicated Account Representatives

Support Resources and Tutorials

Proactive Recommendations

Comprehensive Quality Control

We implement quality control protocols to ensure your custom parts meet your specifications

Quality Assurance

Procedural Inspection Policies

Dimensional Testing & Defect Analysis

eMachineShop’s Quality Parts Guarantee

We ensure parts meet your standards and offer comprehensive customer support

Responsive Customer Support Agents

Corrective Action Recovery Plans

Continual Customer Feedback Integration

Upload your file

for a fast quote

Get a Quote

No CAD file?

Draw it easily with our CAD

GET FREE CAD

Our Software Solutions

eMachineShop offers a range of solutions and software tools that are specifically tailored to the needs of CAD designers and engineers to help streamline the design process and improve efficiency. With these resources, our goal is to make CAD design easy, efficient, and accessible for everyone.