eMachineShop’s Manufacturing Network

Learn More About eMachineShop’s Fully Vetted Manufacturing Network

Discover how our network of carefully selected and fully vetted manufacturing partners can extend your capabilities, lower your costs, and ensure the highest quality of production. Our goal is to streamline your projects, from prototype to production, with efficiency and precision.

Our Selection Criteria

We partner with the best in the business. Our criteria for selecting partners include a proven track record, advanced technological capabilities, robust capacity, and strict adherence to industry standards like ISO 9001. Each partner is rigorously assessed to ensure they meet our high standards.

Utilizing US Local Expertise

We pride ourselves on supporting local economies by partnering with smaller, U.S.-based fabricators and businesses. This collaboration allows us to contribute to community growth while maintaining a high standard of quality and responsiveness. By working closely with these local partners, we ensure that every project benefits from personalized attention and specialized expertise, reflecting our commitment to American craftsmanship and innovation.

Global Partnership Reach

Our network extends globally with strategic partnerships in Europe, Central America, and Asia, enabling us to broaden our capabilities and offer competitive pricing. These international collaborations enhance our ability to deliver a diverse range of services and scale operations efficiently. By tapping into global markets, we access advanced technologies and materials, ensuring that our clients receive the best of both worlds: world-class quality at cost-effective rates.

Quality Assurance — Our Commitment to Quality

Our commitment to maintaining the highest quality standards is unwavering. We conduct regular audits and employ state-of-the-art monitoring systems to ensure consistent quality across all projects. Our network adheres to international quality standards, ensuring reliability and excellence.

How It Works

eMachineShop secures high-quality manufacturing through a strict vetting process. We check part conformity, test raw materials, and require ISO certifications. Regular audits and performance reviews ensure our partners meet our rigorous standards, guaranteeing superior quality and reliability for our clients.

- Part Conformity Assessments: Rigorous inspection and testing to ensure every component meets predefined specifications and quality standards.

- Raw Material Testing: Comprehensive analysis of materials used in production to verify purity, strength, and suitability for end-use.

- International Certifications: Partners are required to hold relevant certifications like ISO, ensuring they meet global standards for quality management and operational procedures.

- Regular Audits: Conducting frequent audits to ensure ongoing compliance with both internal standards and external regulatory requirements.

- Supplier Performance Reviews: Continuous monitoring and evaluation of supplier performance to maintain high-quality production processes.

- Collaborative Quality Control: Working closely with partners to implement quality control measures that align with industry best practices and technological advancements.

- Training and Development: Ensuring that the workforce at manufacturing sites is well-trained in the latest manufacturing techniques and safety protocols.

- Ethical Sourcing Verification: Verifying that partners adhere to ethical sourcing and labor practices to maintain corporate responsibility standards.

Enhanced Capabilities and Client Benefits

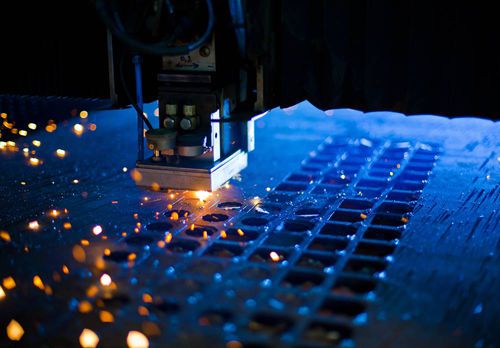

Our network offers a range of specialized services including rapid prototyping, custom CNC machining, and high-volume production. Benefits for our clients include reduced lead times, competitive pricing, and the ability to tackle complex projects with precision.

- Diversified Production Risk:

Distributing manufacturing across different regions helps protect against local disruptions such as natural disasters, political instability, or strikes, ensuring continuous production and delivery. - Tariff Management:

By having manufacturing facilities in multiple countries, your company can navigate and mitigate the impact of tariffs, potentially reducing costs and legal complexities for clients. - Supply Chain Resilience:

A global network reduces dependency on a single supplier or region, safeguarding against supply chain roadblocks such as delays in raw material delivery or regional logistic challenges. - Cost Efficiency:

Manufacturing in regions with lower costs can reduce overall production expenses, which can be passed on as savings to your clients, enhancing their competitiveness.

- Local Market Insights:

Presence in multiple markets allows for better understanding of local consumer preferences and regulations, enabling more tailored products and quicker compliance with regional standards. - Flexibility in Production Capacity:

The ability to shift production between sites in response to demand fluctuations, local events, or holidays avoids downtime, optimizing output and reliability. - Faster Market Access:

Proximity to key markets through localized manufacturing reduces lead times and transportation costs, allowing your clients to speed up the introduction of new products into the market. - Specialized Expertise and Innovation:

Leveraging different capabilities and technologies available in various regions can enhance product quality and innovation. This global expertise provides valuable feedback for specialized fabrication that meets high standards and complex client needs.

Take Advantage — Get a Quote

Explore the full potential of our expansive manufacturing network by submitting a quote today! Take advantage of our local and global partnerships, which allow us to offer unparalleled quality and competitive pricing. Whether your project is big or small, complex or simple, our network is ready to meet your needs with precision and efficiency. Start your journey with us now and see how our tailored manufacturing solutions can enhance your business.

Our Success Stories

Hear from our satisfied clients and see how our network has helped businesses achieve their manufacturing goals. These success stories highlight the effectiveness and efficiency of our networked approach.

Looking for Higher Volume Production Runs?

Through our extensive manufacturing network, we can achieve higher volume production runs without sacrificing the high quality and precision you expect. Our streamlined processes and collaborations with both local and global partners ensure that we can scale up production efficiently. This approach allows us to meet demanding timelines while adhering to the strictest quality standards, making us a reliable choice for large-scale manufacturing needs.

Joining eMachineShop’s Manufacturing Network

Interested in learning more about our network or joining as a partner? Contact us today to explore how we can help enhance your manufacturing network capabilities.