CNC Milling Service

CNC mills or CNC milling machines produce parts of nearly any shape from soft metals like aluminum, harder metals like steel, and plastics such as acetal.

eMachineShop offers cost-effective milling service whether you need a single part, batch of prototypes, or full production order.

- 50+ Materials.

- FREE Shipping in the USA.

- 100% Quality Guaranteed.

Advantages of CNC Milling

CNC milling has a number of advantages over other manufacturing processes.

- Can produce quality parts of almost any shape or form

- Cost-effective machining for prototyping and short runs

- High dimensional tolerances are possible

- Smooth finishes can be achieved

- Can produce identical parts repeatedly

- Milling machines can operate at high speeds, producing parts quickly.

- A single machine can produce a wide variety of part shapes and sizes

- Milling can be applied to many materials, including metals, plastics, and composites.

- CNC machines can be programmed using computer-aided design (CAD) software, which makes it easy to create and change designs.

Design Consideration for Milling

When designing parts to be CNC milled, there are several tips to keep in mind:

- CNC milling machines are capable of precision so try to use this to your advantage

- Avoid deep pockets which are difficult to machine

- Sharp inside corners are often difficult so consider using a radius

- Apply chamfers to top edges to reduce sharpness and improve appearance.

- Apply filters to the bottom of pockets to reduce the possibility of stress fractures if the component will be under stress.

- Thin walls and other flimsy shapes can be difficult to machine as they may not hold up against the pressure of the cutting action.

- Try to create shapes that do not have complex curves in more than one axis – as it may be difficult to hold during machining.

Custom milled parts produced and shipped in a matter of days

eMachineShop offers instant quotes for your precision milled custom parts. Our customer service team will work with you to ensure your design specs are met. Order your part easily by following these steps:

-

Create or Upload your CAD file – Design your parts using our free CAD or upload your CAD files, PDF drawings, or images.

-

Configure your part – Select from over 50+ materials and surface finishes. Enter quantity, address and any special comments to the machinist.

-

Receive a quote – Get a quote for your design (instantly via our CAD).

-

Order your parts – Place your order and receive your quality CNC parts!

eMachineShop Milled Parts

What is CNC Milling?

CNC Milling is an automated machining process used to manufacture 2D and 3D cnc parts by removing material from raw stock. Workshops use CNC milling machines to save time and improve manufacturing productivity.

To make a CNC milled part, a block or sheet is placed on a table below a spindle which holds a cutting tool. A computer selects the tool used, the rotation speed, the vertical motion of the spindle and the horizontal motion of the table. This allows loaded cutters such as drills, taps and end mills to remove portions of the material to create shapes.

CNC Milling is a widely used manufacturing process that produces CNC parts with precision and accuracy. It is a production process which involves the use of a 3D CAD design, tooling, and machine shop equipment such as heavy duty drill presses and CNC machines to produce a custom 3D CAD model. CNC machining can produce CNC parts made from plastic, metal, and other materials with the highest tolerances and surface finishes. It is also used for prototyping and production runs, as it can allow for intricate designs and high precision CNC parts that meet exact specifications and tolerances in a short amount of time. The process is also used to create parts with specific surface finishes. The process ensures that the machined parts have a uniform finish that meets exact specifications and tolerances.

What is a CNC Milling Machine?

A milling machine is designed to produce premium parts with a high level of detail and finish. It uses specialized tooling, such as rotary tools or a milling cutter, to cut away at the raw material by following the instructions from a CAD file to create a part from the design. CNC milling machines remove material to form simple or complex shapes.

A milling machine computer controls the cutter’s function, manufacturing process, milling operation, and coordinates, while minimizing the amount of human input that is required. These machines are involved in the mass production of many components from different materials and plastic. They are designed to save time and reduce manual labor while still producing cnc machined parts that fit within the desired tolerances and scope of the design.

Difference between CNC milling and CNC turning

CNC milling and turning both are capable of producing accurate custom parts from metals, plastic and other materials. The main difference is that while the cutting tools rotate for milling, the raw material rotates for turning. For that reason, turning is mostly used for machining custom cnc round parts such as shafts, pins, balls, etc. Another difference is that while basic milling machines have three axes of motion, a lathe or turning machine needs only two. In a mill, the cutter usually moves up and down while the workpiece moves horizontally in two directions. In comparison, turning requires only that a non-rotating cutter move left and right on one hand and forward and back for the second axis. The fact that turning has only two axes in its simplest form, constrains the variety of shapes it can produce. For example, turning can produce a shaft, chess pawn, a cylinder with a rounded end, etc. Turning normally can’t produce even a simple enclosure box. However advanced turning centers can have more than two axes and therefore can produce a wider variety of shapes.

Why Is CNC Milling Service Important?

CNC services and milling machine options enable efficient and effective manufacturing technologies that efficiently produce custom machined parts and products from plastic and metal that meet exact specifications and tolerances. For instance, CNC milling process can produce a prototype, car parts or aerospace components efficiently.

CNC milling also minimizes the costs of prototyping, saves time, reduces manual labor, and improves the manufacturing process.

This technology isn’t for industrial purposes only. It’s widely used by hobbyists for woodworking, aluminum machining, prototyping and drilling.

The primary function of a milling machine is for cutting workpieces into a desired shape. Based on the number of axes the numerical control cnc machine has, the more complicated the final piece can be. It’s used for aluminum milling, copper milling, steel milling, and numerous other materials such as a variety of hard plastics.

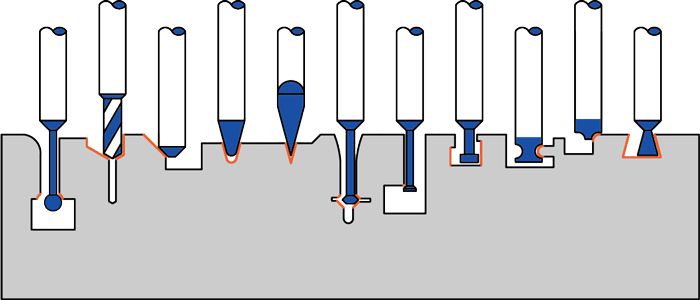

Cutting Tools Used in CNC Mills

Plain End Mill

Creates walls with straight 90 degree edges and sharp corners at the bottom of recesses.

Chamfer End Mill

Creates 45 degree bevels on the top edge of a wall or recess.

Ball End Mill

Creates rounded edges at the bottom edge of a recess.

Rounding End Mill

Creates rounded edges at the top edge of a wall or recess.

Dovetail Cutter

Typically used to cut the pins and tails of dovetail joints.

Considerations for Custom CNC Milling

With custom milling, manufacturers can quickly produce CNC prototypes and durable machined parts for various applications. When selecting CNC machining materials consider that only stainless steel is corrosion resistant. For a lightweight product, low-density metals should be considered such as aluminum, beryllium, titanium, and magnesium alloys.

A CNC milling machine is able to produce highly accurate and precise prototype quickly and efficiently, making it an ideal choice for product development. By using computer-aided design (CAD) software to create a 3D model of the prototype, the CNC milling machine can then create a physical version of that prototype. This allows designers to create and test a single prototype to refine and perfect their design before moving on to mass production.

Elements and alloys able to withstand high machining temperatures include titanium, stainless steel, nickel, and tantalum. Finally, material costs should be considered for custom CNC milling projects since material costs impact total cost.

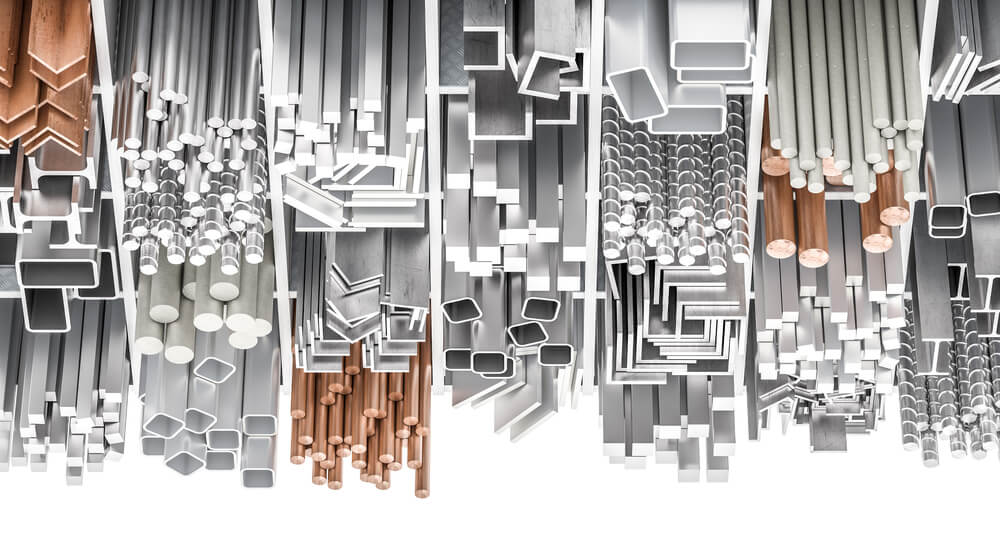

Common CNC Milling Metals

For custom milling projects, any metal or plastic, which is hard enough for machining, can be machined. The most common material used for precision CNC machining by CNC machine shops are aluminum alloys, which are naturally resistant to corrosion.

Aluminum is a commonly used material for CNC milling machine prototypes due to its strength and machinability, making it possible to accurately create intricate features in a single prototype.

The 6000 series is most commonly seen in milling machine shops. Stainless steel alloys are also common since they are resistant to corrosion and wear, as well as carbon steel, titanium, and nylon, a chemically resistant, strong, durable, thermoplastic material.

CNC Milling Copper

Milling copper involves machining components from solid copper bars, and copper blanks. Due to its tough and ductile nature, copper can be difficult to machine. Since copper is a soft metal with a high rate of plasticity, it is prone to deformation under a high cutting force.

CNC milling generates heat during the copper milling process, further enhancing the ductibility of copper. Additional factors which can affect the surface finish while milling copper parts, are tool selection, lubrication, chip load, and the cutting speed and feed.

With the right tools, a CNC machine that can mill aluminum should be capable of milling copper. Milling copper can be achieved using CNC milling services to achieve satisfactory results with minimal burrs, if proper milling procedures are followed and if there is good process control. One method of milling copper involves the use of the multi-pass technique. This technique can enhance the surface finish of milled copper since the technique features a shallow depth of cut.

CNC milling steel

Steel milling involves an alloy of iron and carbon with additives. Machining tools such as CNC mills can also mill stainless steel. Steel is a tough material. The key factor in determining the machinability of stainless steel is the carbon content.

Metal milling

In metal fabrication, the most common process for removing material is milling. Due to their high precision and accuracy, CNC milling machines are often used to cut a variety of metals. Depending on the type of material being used and its strength and hardness, milling can produce different results and finishes. Some metal alloys, such as titanium, are extremely durable and can endure harsh environments. Additional metal alloys include aluminum, copper, brass, zinc, bronze, stainless steel, and steel. Metal milling involves shaping, cutting, drilling and tapping.

Different types of milling machines

Vertical milling machine

A vertical milling machine uses cylindrical cutters oriented vertically on a spindle axis. This

tool is particularly useful for drilling and plunge cuts, thanks to their vertically oriented

tools. Their design allows for all end milling operations.

The vertical milling cutter comes with the following benefits:

- It’s cheaper

- Easier to use

- It is smaller

- Simple set up

- Has straightforward operations and machining processes

- Used to produce high-quality parts for different types of industries and machining processes

Multi-Axis CNC milling machine

The Multi-Axis CNC milling machine can cut at more angles and move along more axes.

4-axis and 5-axis milling machine

These more advanced forms of CNC milling allow for more efficient machining of complex shapes

such as impellers for ships and aircraft propellers. 4-axis and 5-axis machines are frequently used for prototyping. The cutting tools can be positioned at more

angles during the cutting process.

Horizontal milling machine

A horizontal milling process is performed through a horizontal milling cutter. This machine has

horizontally oriented tooling that can move along up to five axes and produce holes, details,

slots, and shapes of three-dimensional parts.

The horizontal milling cutter has these benefits:

- Can generate complex workpiece geometries

- Can accommodate larger parts in most cases

- Better for certain types of cuts

- Higher horsepower

- Fast processing speed

- Better surface finish in some cases

2-axis milling machine

This CNC machining process is much less common as it is limited to just two axis.

3-axis milling machine

The 3-axis tool can move in the x y z axis, so it is possible to cut a workpiece in any

direction, on a vertical or horizontal axis, while performing various milling operations.

However, this machine does come with some limitations. The uniform angle of the 3-axis milling

machine reduces its ability to cut some complex production parts.

CNC milling machine – parts

Below you can find the list of the general components most CNC machine tools have.

- Frame: The frame provides stability and rigidity. It features other components like a base, headstock, and detachable columns.

- Spindle: The spindle is the rotating unit of the CNC machine that holds the cutting tool and other parts in place. It can be horizontal or vertical.

- Coolant tank: CNC milling processes generate heat. A coolant tank helps cool the process for quality surface finishes and long tool life.

- Control panel: A CNC control panel is used for entering data and codes. It controls milling operations.

- Tool holders: This component holds the cutting tools to the CNC machine.

- Table: This is the solid base where you place the clamps and workpieces using a vice or fixtures.

- Axes: The general axes are x y z to support the full milling process.

Industries that benefit the most from CNC machined parts

The CNC milling process is applicable to many industries as it is highly efficient, accurate and eliminates the need for manual labor. Whether it is for prototypes or a full production runs, machine shops and their services are a critical step in the manufacturing process.

The electronics industry heavily relies on CNC machines and CNC milled parts to create electronic enclosures, circuit supports and other related components for their products.

Commercial industryCNC cutting heads are capable of making affordable commercial parts that help companies cut back on production costs and save time in the process. They will use a machine shop’s milling services in their manufacturing processes to produce a wide variety of mechanical parts.

Oil and gas industryThese machines are used in the petrochemical industry to produce drill bits, cylinders, pins, rods, valves, and many other components.

The medical industry is another field where CNC milling tools help create various production parts such as implants and medical devices. CNC milling is often used to create surgical equipment and components, including ventilator parts, insulin pumps, medical rods and implants, bone plates, and medical screws.

Aerospace industryThe aerospace industry has a constant need for CNC machined parts. This type of machine can make complex, customized components which are part of aerospace equipment. Some commonly created parts include electronic enclosures, landing gear, hydraulic manifolds, housings, fuel bodies, and bearing houses.

What Our Customers Say

Compatible Materials

Frequently Asked Questions

Q: What is a cnc mill?

A: A CNC mill machine uses computer numerical control to create various types of components. CNC mill machines are commonly used in the manufacturing industry to create parts for cars, computers etc. Desktop CNC mills are smaller versions of these machines that can be used for small-scale applications.

Q: What is 3 axis cnc machine?

A: A three-axis CNC machine is a computer-controlled machine tool that has three axes of motion: the X-axis, the Y-axis, and the Z-axis. A three-axis CNC machine can perform many different machining operations, such as drilling, milling, turning, and engraving.

Q: What can you make with a milling machine?

A: Milling machines are most commonly used in machine shops, where they are used to create parts for a variety of industries. They can be used to create both small and large parts and can be fitted with a variety of attachments to perform different tasks.