A tolerance stack is a calculation to determine how tolerances accumulate. Stacks help establish and optimize part tolerances, and ensure that parts are designed to promote maximum function at minimal cost. When used in the design stage, stacks provide an opportunity to evaluate a part’s manufacturability, which reduces the need for costly prototypes.

The ground rules for stacks are very similar to those for GD&T in general:

- Parts are assumed to be at room temperature

- Parts are manufactured to print

- There is no part wear

- No other unusual conditions (contamination, etc.) exist

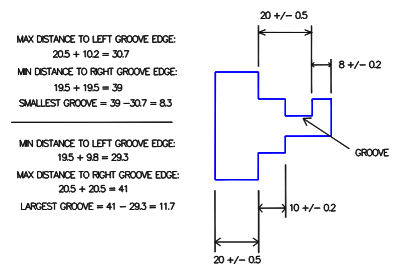

The example below shows a basic stack that determines the minimum and maximum width of a groove. The example indicate that if the dimensions shown are all manufactured within tolerance, the groove size could vary between 8.3 and 11.7. That’s a variation of 3.4 even though each dimension has a tolerance of no more than 0.5. Had the part been made without computing the stack the groove might have been substantially smaller or larger than expected, resulting in a poor or impossible fit with a mating part.

Performing the tolerance stack before building parts allows a designer to catch issues before they create expensive problems.