Many part designs contain surfaces that need to be uniform. In GD&T flatness tolerance defines a zone between two parallel planes within which a surface must lie. Since flatness is applied to an individual surface, this tolerance does not need to be related to a datum. Flatness is usually used on a surface associated with a size dimension, acting as a refinement to the size requirement to ensure proper function of a part, or to promote even wear. Flatness tolerance applies in all drawing views, not just the view showing the tolerance callout.

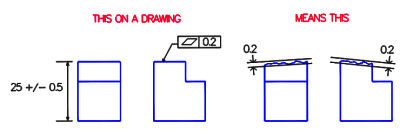

An example of flatness is shown below. The left figure shows the drawing callout. The boxed symbols can be read “this surface must lie between two parallel planes spaced 0.2 apart in all views.” The right figure shows a possible actual part condition. Note that the flatness tolerance must be less than the size tolerance associated with the surface. If the flatness tolerance had been 0.6, it would result in a condition where the overall size of the part may have exceeded its allowable size limits.

Because flatness refines a surface, it may be used in a tolerance stack.