Materials and Finishes

Aluminum 6061 – for machined parts

Aluminum 5052 – for sheet metal parts with bends

Stainless 304 – popular stainless steel

Steel 1008/1018 – economical steel

Brass 360 – for decorative and low friction parts

Acetal Black – general plastic

Aluminum 5052 – for sheet metal parts with bends

Stainless 304 – popular stainless steel

Steel 1008/1018 – economical steel

Brass 360 – for decorative and low friction parts

Acetal Black – general plastic

Select a Material

- Choose menu Job > Material.

- On the bottom of the materials dialog, check “Allow substitution” for the preferred materials that suit your part.

- In the grid, select the desired material by clicking on it.

- On the bottom of the materials dialog, review and check the desired boxes.

- Click OK.

Specify Special Materials

You can specify a material other than what is offered in the material list.

- Choose menu Job > Material.

- On the top of the window, select the “Request Special Material” tab.

- In the text field, enter a description of the desired material. If you have a suggested vendor, you may specify it here as well.

- Click OK.

Specify Pre-Shaped Stock

Pre-shaped stock is material that comes in special forms other than sheets, plates, blocks or rods (e.g. L beams, rectangular tubes, hexagonal, etc).

Using pre-shaped stock doesn’t always reduce price.

- Provide the supplier material ID via Comments To Machinist if your part is stock material modified without reducing the size of the outermost region.

- Request a manual quote.

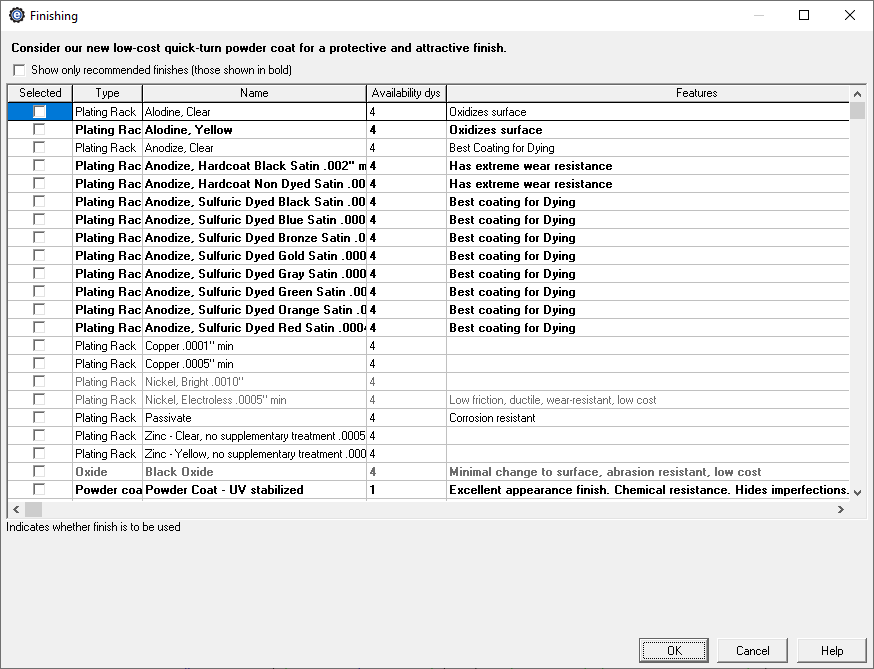

Specify a Finish

Finishes treat the surface of your part.

Apply finishes to your part for decorative or functional purposes.

- Choose menu Job > Finishing.

- Check the desired finish.

- If needed, enter any additional settings that may appear below the grid.

- Click OK.

Note: You may need to compensate for finish thickness.

Specify Material Color

- Choose menu Job > Material.

- From the list and corresponding dropdowns, check the desired material and color of the material.

- If specifying a special material, in the text field, specify the desired color.

- Click OK.

- If desired, choose menu Job > Finishing and select a colored finish from the list.