Ordering

Analyze and Price a Design

The Analyzer scans your design and gives you instant feedback including warnings and errors. It will also instantly price your design.

Run the Analyzer periodically during your design process.

- Choose menu Job > Price/Analyze.

- On the right sidebar, review warnings and error messages displayed. If you click an error or warning, the corresponding part of your design will be highlighted.

- Resolve as many issues as possible to ensure the job will run smoothly and ship on time.

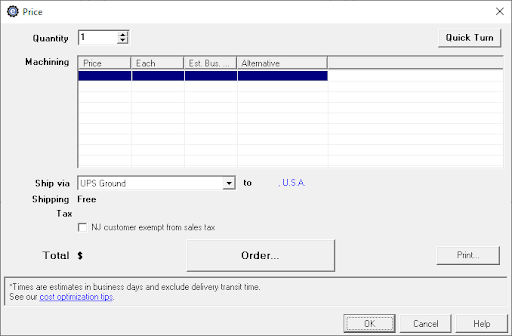

- The pricing dialog will appear, where you can specify the quantity and view the price.

Place an Order

- Choose menu Order > Review & Place Order.

- On the top of the pricing dialog, set the desired quantity.

- Choose a shipping method, and click Order.

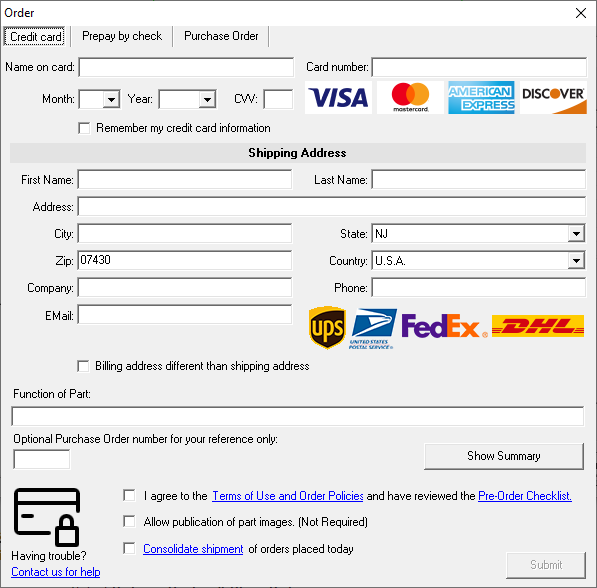

- In the secure order dialog, enter the necessary information.

- Click Submit.

Order Options

Consolidate Orders

Requesting shipment consolidation can reduce shipping costs.

- Orders to be consolidated must be placed on the same day.

- Choose menu Order > Review & Place Order and click Order.

- On the bottom of the order dialog, check Consolidate shipment of orders placed today.

- Orders marked for consolidation will only be held for up to 5 business days after completion.

Quick Turn Orders

Quick Turn Orders

Quick turn orders are offered for faster delivery (subject to acceptance review).

- Choose menu Order > Review & Place Order.

- In the pricing dialog, view the quick turn price and time options.

Quick turn orders must follow these specifications:

For 3D jobs:

- Material: Aluminum 6061.

- Small quantity (the threshold will be computed).

- Min (x,y,z) ≤ 2.9 inch.

- Mid (x,y,z) ≤ 11.9 inch.

- Max (x,y,z) ≤ 29 inch.

- No finishes.

- No user defined threads.

- Uncheck menu Job > Settings > Processes Required.

- No Comments To Machinist.

- Turned parts are currently not supported for quick turn.

- Tolerances ≥ +/- .005″.

- Inside corner arcs ≥ .125″.

- Roughness ≥ 63.

For 2D jobs:

- Material: Aluminum 6061 or 5052.

- Small quantity (the threshold will be computed).

- Mid (x,y,z) ≤ 23 inch.

- Max (x,y,z) ≤ 47 inch.

- No finishes.

- No Comments To Machinist.

- Tolerances ≥ +/- .01″.

- Edge roughness ≥ 250.

Get Order Status

- Choose menu Order > Request Order Status.

- On the launched webpage, enter the required information.

Pre-Order Checklist

Carefully check your design before ordering to ensure parts satisfy your needs.

- To get the lowest price possible, ensure your design adheres to our cost-reduction tips as closely as possible.

- For all lines, check the position, numeric bar settings, and information on the status bar.

- Use a magnified view to review intricate areas of your design.

- Use menu View to look at all relevant views in 2D and 3D.

- Use menu View > Model Bends to analyze bends and ensure they fit.

- Select each command in the Job menu and review all information.

- Review and confirm machining specifications.

- Check for missing features, etc. to ensure completeness.

- Ensure that every important tolerance and specification is specified. See eMachineShop’s general tolerance limits.

- Parts may be vibratory tumbled to remove sharp corners. Specify otherwise if needed.

- Add any desired finishes, such as powder coating, etc.

- Ensure that parts fit together properly.

- Carefully read and resolve as many advisory messages as possible.

- Reordered parts may vary from prior orders. Use tolerances to specify allowable ranges.

Request a Manual Quote

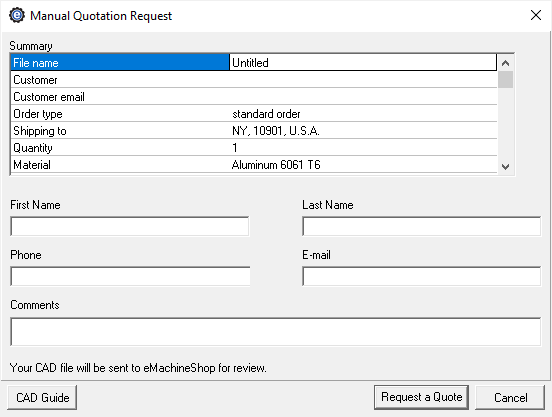

In some circumstances you may deem it necessary to have your design manually quoted.

- Press keys Ctrl + Alt + F3.

- In the window that pops up, enter the necessary information.

Cost Reduction Guide

Reduce the cost of your parts by designing with these tips.

See our cost-reduction page to get the lowest price for your parts.