Materials

Whether for a hobby project or large-scale commercial application, eMachineShop has the inventory and supplier connections to meet your requirements.

Review our available materials below. If you don’t see a material that suits your needs, you can request it.

- FREE Shipping in the USA.

- No Minimum Order Quantity.

- 100% Quality Guaranteed.

Choosing Materials

The tips below may help you determine what type of material is best suited for your parts:

-

Metals yield higher tolerance parts than plastics.

Metals yield higher tolerance parts than plastics. -

Plastics can warp slightly over time due to moisture absorption and heat exposure but are typically less expensive to manufacture than metals.

Plastics can warp slightly over time due to moisture absorption and heat exposure but are typically less expensive to manufacture than metals. -

Sheet metal parts usually cost less than machined parts.

Sheet metal parts usually cost less than machined parts. -

Materials that don’t require secondary finishing, such as stainless steel and aluminum, tend to be the most cost-effective options for prototyping and low-volume orders.

Materials that don’t require secondary finishing, such as stainless steel and aluminum, tend to be the most cost-effective options for prototyping and low-volume orders.

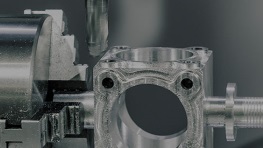

Aluminum

One of the most popular manufacturing metals due to its machinability, low cost, and light weight. Used in vehicles, construction applications, and consumer goods.

Brass

Typically comprised of copper and zinc. This alloy has a gold appearance and is easy to machine. Commonly used to make components for appliances and musical instruments.

Bronze

Typically comprised of mostly copper and some tin. It’s ductile, corrosion resistant, and is commonly used to make springs, and award medals.

Copper

Malleable, high corrosion resistance, and high electrical and thermal conductivity. Often used in wire, heat sinks and pipes.

Steel

Available in numerous alloys, many of which are strong, inexpensive, and easy to machine. Commonly used in railways, enclosures, and household appliances.

Stainless Steel

Known for its shiny appearance, high corrosion resistance, and self-protective properties. Often used to make cookware, automotive parts, and hand tools.

Spring Steel

Has high yield strength and is resistant to deformation. Ideal for automotive springs and other suspension applications.

Titanium

A hard metal with a high strength-to-weight ratio and corrosion resistance. Often used in engines, aerospace technology, and industrial equipment.

ABS

Highly resistant to impact, acids, and oils. Often injection molded into parts used in pipe systems, wheel covers, and protective equipment.

Acetal

Also known as “Delrin”, this plastic has high impact resistance and good dimensional stability. Used to make gears, safety locks, and cutlery.

Acrylic

Has high dimensional stability and weather resistance, and is transparent. Used to make exhibit enclosures, windows, and gears.

Laminated Fiberglass

This reinforced plastic is cheaper and more flexible than carbon fiber. Ideal for roofing, water tanks, and aircraft components.

Nylon

High tensile strength and heat resistance. Commercial applications include bushings, wear plates, nuts and bolts, and gears.

Polycarbonate

Biologically inert plastic, naturally transparent and highly resistant to impact. Typical applications include instrument panels, containers, and protective gear.

Polyethylene

This thermoplastic has a high melting point, insulative properties, and impressive resistance to most solvents, oils, alcohol, acids, and alkalis. Used to make plastic bags and consumer goods.

Polypropylene

Chemically inert, low-density, and highly flexible. Frequently used to make hinges, plating barrels, and transportation equipment.

Polystyrene

Non-toxic, insulative, and highly resistant to water, bacteria, and mildew. Used to make packaging, insulation, and lab equipment.

PTFE

Also known as “Teflon”, this plastic remains stable in extreme temperatures and has a low coefficient of friction. Widely used in rotating and sliding mechanisms.

PVC

Flame-retardant and resistant to most inorganic chemicals. Used in pipes, wire insulation, and electronic enclosures.

Rubber

Available in many organic and synthetic forms. Typical applications include grips, gaskets, and seals.

NBR Nitrile

Exceptional resistance to oils and solvents, but low weatherability. Applications include seals, O-rings, and hoses.

Neoprene

Excellent abrasion resistance and weatherability. Applications include gaskets, window seals, and sporting equipment.

Silicone

Flexible, highly resistant to sunlight and oxidation, and has noteworthy insulative properties. Applications include adhesives for protecting fuel tanks, vent ducts, and wiring.