Custom Pulley Design Software

Design custom pulleys easily. Download eMachineShop’s free CAD to start with a pulley design from our extensive library of parts and shapes. When you’re done customizing your pulley, have it analyzed and quoted for manufacturing right in the software.

- 100k+ CAD Users.

- Hundreds of Part Templates.

A pulley is a wheel that turns on a shaft to support the movement of a rope, cable, chain or belt. There are 3 types of pulley setups: fixed, moveable, and compound. Fixed pulleys attach to a structure, stay in one place, and change the direction of exertion on the belt or rope. An example would be a flagpole hoist. Moveable pulleys are used with fixed pulleys and are able to move vertically as seen in gym weight machines and construction cranes. Compound pulleys are categorized as the many combinations of fixed and moveable pulleys. Depending on the application, pulleys can be designed with rounded, square, or V-shaped grooves to guide for the rope or belt. Pulleys are commonly used for applications ranging from block and tackle assemblies to hoists and automotive applications. Download eMachineShop CAD to customize your own pulley design and get in-software manufacturing quotes out of materials including steel, aluminum, and brass.

Make a Custom Pulley

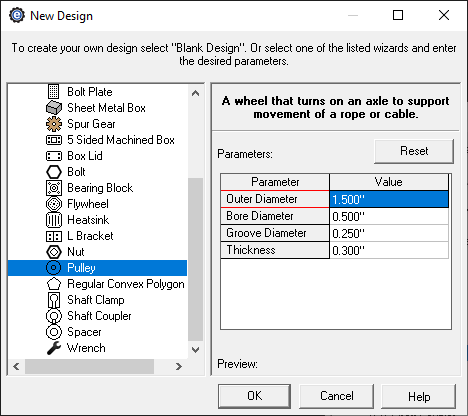

- Open eMachineShop CAD and select File > New.

- Click the Wizards dropdown.

- From the list, select Pulley.

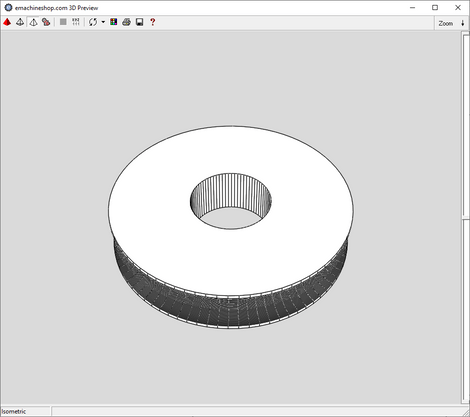

- Enter the desired parameters and click OK.

- In the workspace, add desired custom features as needed.

For Different Types of Pulleys

- Select File > New.

- Click the 3D Samples dropdown.

- Find and select from the available types of Pulleys.

- In the workspace, add desired custom features as needed.

Manufacturing Capabilities

CNC Milling

Mills use rotating tools to cut material into almost any 3D shape. CNC Mills can work with tight tolerances.

Injection Molding

Injection Molding produces parts by forcing molten polymer material into a mold. It’s the most economical process for producing high volumes of plastic parts.

3D Printing

3D Printing (aka Rapid Prototyping) is an additive manufacturing process. It’s often used for testing designs and quick-turn low-volume 3D parts.

CNC Turning

CNC Lathes feed cutting tools into rotating material. Turning is mainly used to produce precise, cylindrical parts.

CNC Waterjet Cutting

Waterjets mainly cut sheet material into 2D parts using a high-pressure stream of water and abrasive. Waterjet cutting is suitable for most materials and yields clean edges.

CNC Laser Cutting

Laser cutting is often used to produce 2D parts from sheet metal. A laser beam vaporizes a cut path to achieve the desired shape. Great for prototypes and short runs.

Sinker and Wire EDM

EDM machines create parts by using recurring sparks to remove material. Recommended for intricate designs requiring sharp inside corners and high dimensional accuracy.

CNC Plasma Cutting

CNC Plasma Cutters use a high-velocity stream of ionized gas to cut parts out of sheet metal. Excellent for producing 2D parts when working with thick metal sheets.

Compression Molding

Rubber Compression Molding creates parts by pressing a heated block of rubber into a mold. Ideal for making high volumes of simple rubber parts.

CNC Routing

CNC Routing creates precise cuts in sheet materials by removing material with a rotating tool.

Secondary Processes

After manufacturing, parts may require additional processing. Secondary services include CNC bending, grinding, tapping, knurling and more.

Surface Finishing

Finishing processes are used to enhance appearance, surface durability, and corrosion resistance. Options include powder coating, anodizing, plating, polishing and more.