CUSTOM ENERGY PARTS

PRECISION ENERGY PARTS ON DEMAND

We’ve made custom parts for energy applications including:

- Windmills

- Solar Panels

- Brackets & Sleeves

- Generators

- Seals

- Energy Storage

- Valve Components

YOUR TRUSTED MANUFACTURING PARTNER

MACHINING CAPABILITES

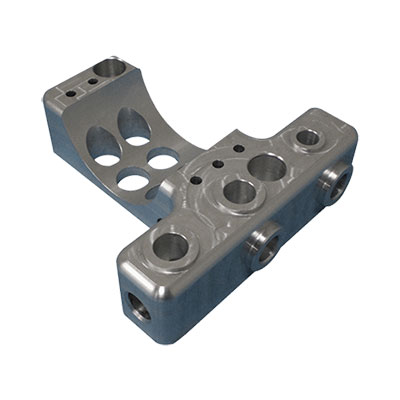

CNC Milling

Mills use rotating tools to cut material into almost any 3D shape. CNC Mills can work with tight tolerances.

Injection Molding

Injection Molding produces parts by forcing molten polymer material into a mold. It’s the most economical process for producing high volumes of plastic parts.

3D Printing

3D Printing (aka Rapid Prototyping) is an additive manufacturing process. It’s often used for testing designs and quick-turn low-volume 3D parts.

CNC Turning

CNC Lathes feed cutting tools into rotating material. Turning is mainly used to produce precise, cylindrical parts.

CNC Waterjet Cutting

Waterjets mainly cut sheet material into 2D parts using a high-pressure stream of water and abrasive. Waterjet cutting is suitable for most materials and yields clean edges.

CNC Laser Cutting

Laser cutting is often used to produce 2D parts from sheet metal. A laser beam vaporizes a cut path to achieve the desired shape. Great for prototypes and short runs.

Sinker and Wire EDM

EDM machines create parts by using recurring sparks to remove material. Recommended for intricate designs requiring sharp inside corners and high dimensional accuracy.

CNC Plasma Cutting

CNC Plasma Cutters use a high-velocity stream of ionized gas to cut parts out of sheet metal. Excellent for producing 2D parts when working with thick metal sheets.

Compression Molding

Rubber Compression Molding creates parts by pressing a heated block of rubber into a mold. Ideal for making high volumes of simple rubber parts.

CNC Routing

CNC Routing creates precise cuts in sheet materials by removing material with a rotating tool.

Secondary Processes

After manufacturing, parts may require additional processing. Secondary services include CNC bending, grinding, tapping, knurling and more.

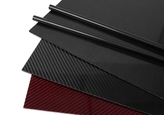

Surface Finishing

Finishing processes are used to enhance appearance, surface durability, and corrosion resistance. Options include powder coating, anodizing, plating, polishing and more.